Manchester lab develops new, cleaner and faster way to make valuable molecules

Researchers at The University of Manchester have discovered a more efficient way to develop valuable chemicals needed for medicines by combining proteins and metals in the manufacturing process.

New research published today, in Nature Catalysis, demonstrates a new way of merging natural and synthetic catalysts to deliver more efficient and sustainable routes to pharmaceuticals and other valuable chemical products.

Currently chemical synthesis is used to construct many of the molecules that we rely on, from medicines that combat disease and agrochemicals to boost crop yields, through to plastics and other materials that are used in all aspects of daily life.

It is widely recognised that these traditional chemical processes are increasingly unsustainable, relying on non-renewable ingredients, highly toxic or otherwise deleterious reagents and solvents, and can create harmful emissions and waste streams.

Chemicals production also relies on multi-step synthetic routes that are expensive, meaning that many valuable products, including some essential medicines are only available to a privileged few within affluent nations.

To address these major problems, a team of chemists from The University of Manchester have devised a way of combing natural and synthetic catalysts to speed up the chemical manufacturing process.

We are optimistic that the new integrated catalytic processes we have developed could lead to cleaner, safer and more cost-effective ways to make chemical products, such as new pharmaceuticals, which is important for a more sustainable future.

Professor Jason Micklefield who led the study said: “We are optimistic that the new integrated catalytic processes we have developed could lead to cleaner, safer and more cost-effective ways to make chemical products, such as new pharmaceuticals, which is important for a more sustainable future.

“We used bacterial cells with the enzyme produced inside. In this way the cell membrane prevents the enzyme coming into contact with the metal catalyst but allows the small molecule building blocks to flow through. We also deployed enzymes in a membrane made of cross-linked fibres, from wood pulp, rather like a tea bag but with smaller holes, which allowed us to remove and recycle the enzymes.”

“The main advantage is that everything is done in water which is clean and safe. Most of the current processes use organic solvents which are toxic, flammable and dangerous to the user and the environment. The use of multiple catalysts also means that we do not need to use additional dangerous and undesirable chemical reagents (acids, bases & oxidising agents etc.) which are typically required in traditional processes.”

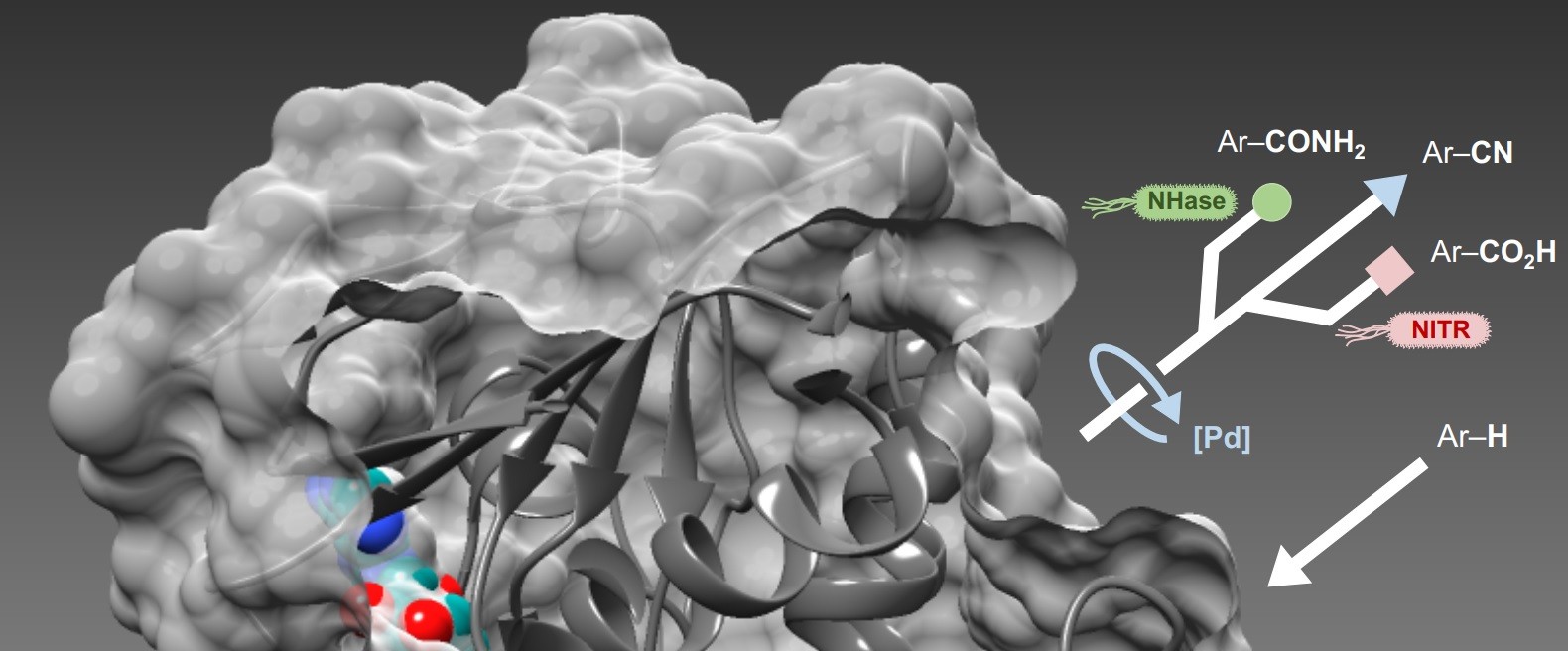

The scientists used enzymes (natural protein catalysts) that had been modified to improve their properties together with non-natural metal catalysts. Normally it is not feasible to use these different types of catalysts together as they deactivate one another and consequently they would be deployed in separate laborious and costly multi-steps processes.

To overcome these compatibility issues, the team developed ways to compartmentalise the different catalysts, so that they could be used in a single integrated process. Rather than using typical toxic chemical reagents and solvents, the new integrated processes can be performed in water, to deliver pharmaceuticals and other target products by a more direct, environmentally friendly and cheaper route.

Various enzymes were used, but the key enzyme was a halogenase enzyme which installs halogen atoms (chlorine or bromine) into the precursors (building blocks). The halogen atoms are reactive and can be used create new bonds between the build blocks enabling the assembly of larger molecules. Mutations were then introduced into the haloganese enzyme changing its shape so that it could accept a wider range of different building blocks.

The new research details a way to make molecules more cleanly, safely and efficiently in fewer steps. If adopted in industry, it would reduce problems of chemical waste and potentially lead to more affordable products, including medicines which could be made more widely available to help treat antimicrobial resistance (AMR) and neglected diseases in the developing world along with antiviral agents to deal with the threat of current and new viral pandemics. All of which are currently expensive produce as they are manufactured by laborious multi-step routes.